Dosing Systems

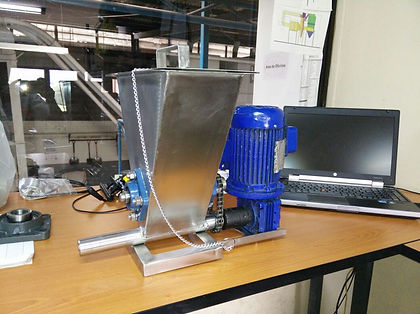

Micro-ingredient systems use dosing cells, each with a dosing screw. Rotary discharge equipment can be provided as an option for products with poor flow characteristics. The dosing screws discharge into one or more weigh hoppers, depending on the total number of ingredients. The dosing screws are available in different diameters and pitches to match the ingredient flow characteristics. In modern feed mills, micro-ingredient dosing often operates in-line with the central batch system. Dosing systems feature high accuracy and fully automatic controlled process. To ensure an accurate dosing and weighing process, ingredients must be dosed to the weighing hopper in a controlled manner. Depending on the ingredient and process needs, a variety of dosing components can be used, including screw feeders for difficult-to-feed products, vibrating feeders for gentle handling and low energy consumption, dosing pumps for liquid ingredients, rotary airlocks and belt conveyors.